EMC and signal integrity

We help you design for EMC & signal integrity from the outset: clean return paths, robust decoupling, controlled impedance and effective filtering & shielding. Early SI/EMC input keeps iterations down and makes compliance smoother.

Concept and layout review

We review segmentation (analog/digital/power), reference planes and return-path continuity. Placement and routing guidance reduces loop area and common-mode noise sources.

Impedance, decoupling and PI

Stackup and target impedances, capacitor networks and placement, via strategies, and guidance on supplies, clocks and sensitive nodes—aligned with your manufacturer’s capabilities.

Filtering, shielding and cabling

Practical filter choices (CM/DM chokes, RC/LC), shield terminations, enclosure grounding and connector strategies—including ESD paths and creepage/clearance where relevant.

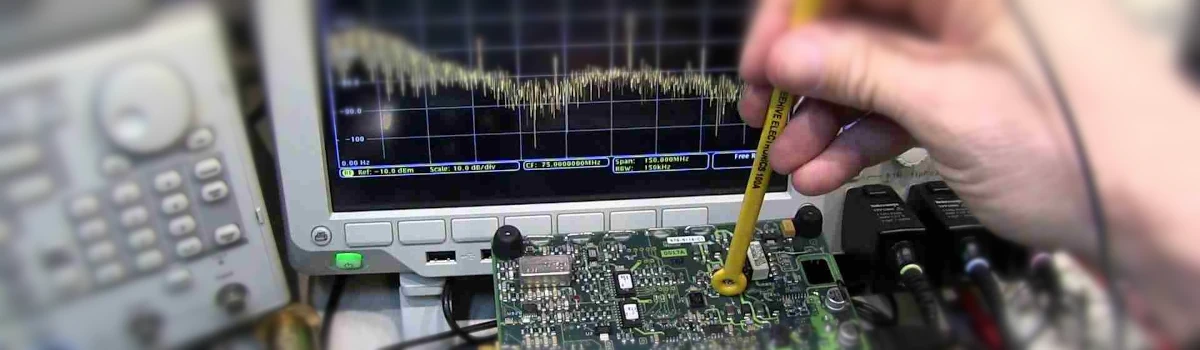

Pre-compliance and lab coordination

Pre-compliance measurements for emissions and immunity with clear pass/fail criteria. We prepare compliance test plans and coordinate with external labs for CE/RED where applicable.

Documentation and handover

- EMC/SI review notes and layout constraints

- Stackup & impedance tables

- Filter BOM and grounding/shielding instructions

- Test plan and pre-compliance results

Why work with us?

- Early, practical EMC/SI input that reduces re-spins

- Reviews integrated with PCB layout & manufacturing

- Short, predictable lead times in Sweden

Ask an EMC engineer

Send schematics, stackup and constraints via our contact form — we’ll respond quickly with a review approach, lead time and cost. Fast prototyping and test & quality are available in the same flow.

Related: electronic engineering · pcb layout · embedded systems & firmware · product development