Electronic engineering

We provide electronic engineering from requirements and component strategy to verified design, documentation and handover to production. With DFM/DFX, clear design rules and close collaboration with our manufacturing in Kungsbacka (near Gothenburg), we reduce risk, lead time and cost.

Requirements and architecture

We define the requirements, use cases and system architecture. BOM with alternates, lifecycle/availability checks and a practical risk analysis underpin a robust design.

Schematics and component strategy

We capture schematics with attention to reference design constraints, power integrity, decoupling and protection. Component choices consider cost, availability and future-proofing.

Designed for manufacturing (DFM/DFX)

Engineering works hand in hand with PCB layout to ensure manufacturability, testability and cost efficiency. EMC & signal integrity are addressed early to avoid late iteration.

Embedded and firmware collaboration

When needed, we involve our embedded systems & firmware team for bring-up, drivers, RTOS/bare-metal and connectivity (CAN, BLE, Wi-Fi, Ethernet) to validate the design together with hardware.

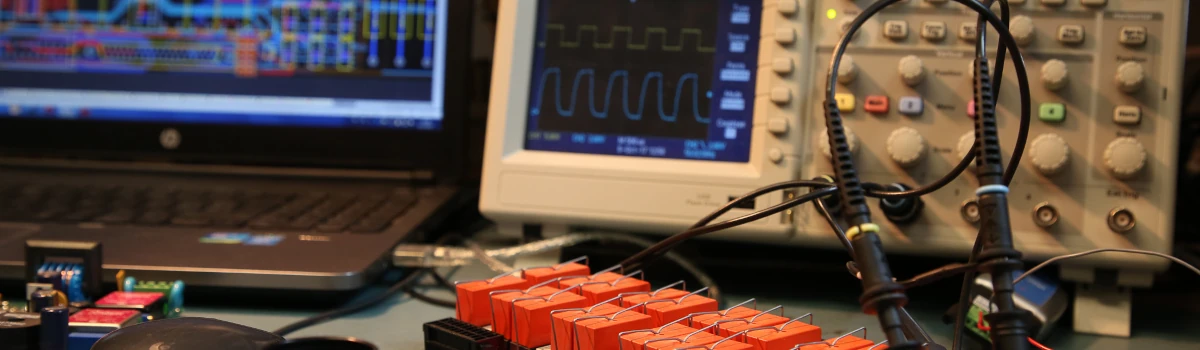

Prototype and verification

Fast prototyping and test & quality in the same flow. We plan measurements, test cases and corrective actions for a predictable route to series.

Why work with us?

- End-to-end responsibility from requirements to verified prototype

- Practical DFM/DFX and short path to production

- Close collaboration between HW, FW and test

- Short, predictable lead times in Sweden

Get a quote or ask an engineer

Send your inputs (BOM, drawings, Gerber/ODB++) via our contact form — we’ll get back quickly with an approach, lead time and cost.

Related: PCB layout · embedded systems & firmware · EMC & signal integrity · product development